Page 52 - Technical Guidbook - Zika industrial Welding Supplies

P. 52

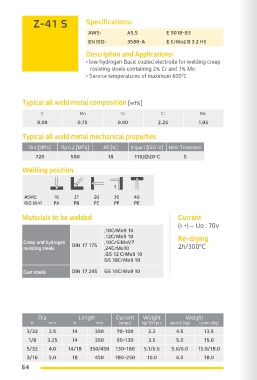

Z-41 S Specifications: Specifications: Z-46

AWS: A5.5 E 9018-B3 AWS: A5.5 E 9018-D1

EN ISO: 3580-A E CrMo2 B 3 2 H5 EN ISO: 2560-A E 50 5 MnMo B 3 2 H5

Description and Applications: Description and Applications:

• low hydrogen Basic coated electrode for welding creep • Basic coated electrode suited for welding high

resisting steels containing 2% Cr and 1% Mo tensile structural steels, working at very low

o

• Service temperatures of maximum 600 C temperatures

• Low diffusible hydrogen content

Typical all weld metal composition [wt%] Typical all weld metal composition [wt%]

C Mn Si Cr Mo C Mn Si Mo

0.09 0.75 0.40 2.25 1.05 0.07 1.45 0.40 0.35

Typical all weld metal mechanical properties Typical all weld metal mechanical properties

Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment

720 580 18 110J@20°C S 650 600 23 130J@-29°C S

80J@-51°C

Welding position Welding position

ASME: 1G 2F 2G 3G 4G ASME: 1G 2F 2G 3G 4G

ISO 6947 PA PB PC PF PE

ISO 6947 PA PB PC PF PE

Materials to be welded Current Materials to be welded Current

)= +( ~ Uo : 70v )= +( ~ Uo : 70v

,10CrMo9 10 General structural St 33, St 37.2 to St 52.3

,12CrMo9 10 Re-drying steels DIN 17 100 DOMEX 400TE, 450, 480 Re-drying

Creep and hydrogen DIN 17 175 ,10CrSiMoV7

resisting steels ,24CrMo10 2h/300ºC Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5 2h/300ºC

,GS 12 CrMo9 10 vessel steels

GS 18CrMo9 10 Fine grained steels USS-T

Cast steels DIN 17 245 GS 19CrMo9 10

Dia Length Current Weight Weight Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg( in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

3/32 2.5 14 350 70-100 2.2 4.5 13.5 3/32 2.5 14 350 75-110 2.1 5.0 15.0

1/8 3.25 14 350 90-130 3.5 5.0 15.0 1/8 3.25 14 350 110-140 3.6 5.0 15.0

5/32 4.0 14/18 350/450 130-180 5.1/6.6 5.0/6.0 15.0/18.0 5/32 4.0 14 350/450 150-190 6.0 5.0/6.0 15.0/18.0

3/16 5.0 18 450 180-250 10.0 6.0 18.0 3/16 5.0 18 450 190-260 11.2 6.0 18.0

54 55