Page 42 - Technical Guidbook - Zika industrial Welding Supplies

P. 42

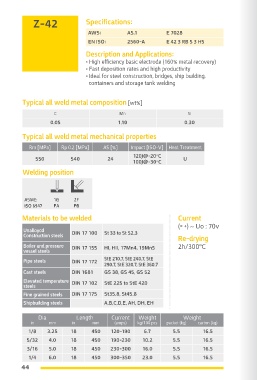

Z-42 Specifications: Specifications: Z-47

AWS: A5.1 E 7028 AWS: A5.1 E 7048

EN ISO: 2560-A E 42 3 RB 5 3 H5 EN ISO: 2560-A E 42 3 B 3 5 H10

Description and Applications: Description and Applications:

• High efficiency basic electrode (160% metal recovery) • Vertical down welding basic electrode

• Fast deposition rates and high productivity • Recommended for welding in shipbuilding construction

• Ideal for steel construction, bridges, ship building, • Very little slag and spatter loss

containers and storage tank welding • High welding speed

Typical all weld metal composition [wt%] Typical all weld metal composition [wt%]

C Mn Si C Mn Si

0.05 1.10 0.30 0.08 1.00 0.60

Typical all weld metal mechanical properties Typical all weld metal mechanical properties

Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment

120J@-20°C 530 430 26 100J@-30°C U

550 540 24 U

100J@-30°C

Welding position Welding position

ASME: 1G 2F 3G 3G

ASME: 1G 2F ISO 6947 PA PB PG PF

ISO 6947 PA PB

Materials to be welded Current Materials to be welded Current

)= +( ~ Uo : 70v General structural DIN 17 100 St 33 to St 52.3 )= +( ~ Uo : 70v

Unalloycd steels

Construction steels DIN 17 100 St 33 to St 52.3 Re-drying Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5 Re-drying

Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5 2h/300ºC vessel steels 2h/300ºC

vessel steels DIN 17 172 StE 210.7, StE 240.7, StE

Pipe steels DIN 17 172 StE 210.7, StE 240.7, StE Pipe steels 290.7, StE 320.7, StE 360.7

290.7, StE 320.7, StE 360.7 DIN 1626-1630 St 37.0/4, St 44.0/4, St 52.0/4

Cast steels DIN 1681 GS 38, GS 45, GS 52 Cast steels DIN 1681 GS 38, GS 45, GS 52

Elevated temperature DIN 17 102 StE 225 to StE 420 Elevated temperature

steels steels DIN 17 175 St 35.8, St 45.8

Fine grained steels DIN 17 175 St35.8, St45.8 Fine grained steels DIN 17 102 StE 255 to StE 420

Shipbuilding steels A,B,C,D,E, AH, DH, EH Shipbuilding steels A,B,C,D,E, AH, DH, EH

Dia Length Current Weight Weight Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg( in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

1/8 3.25 18 450 120-190 6.7 5.5 16.5 3/32 2.5 14 350 70-90 1.7 5.0 15.0

5/32 4.0 18 450 190-230 10.2 5.5 16.5 1/8 3.25 14 350 90-140 2.9 5.0 15.0

3/16 5.0 18 450 230-300 16.0 5.5 16.5 5/32 4.0 18 450 135-185 4.4 6.0 18.0

1/4 6.0 18 450 300-350 23.0 5.5 16.5 3/16 5.0 18 450 175-255 8.9 6.0 18.0

44 45