Page 73 - Technical Guidbook - Zika industrial Welding Supplies

P. 73

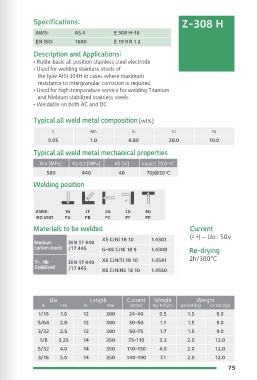

Z-308 Specifications: Specifications: Z-308 H

LHR AWS: A5.4 E 308 L-16 AWS: A5.4 E 308 H-16

E 19 9 L R 5 3 mod

EN ISO:

1600

1600

E 19 9 R 1 2

EN ISO:

Description and Applications: Description and Applications:

• For welding austenitic Cr- Ni steels. • Rutile-basic all position stainless steel electrode

• Rutile coated high recovery (145%) electrodes. • Used for welding stainless steels of

• Used whenever a high deposition rate is required. the type AISI 304H in cases where maximum

• Easy slag release, smooth and finely rippled deposit. resistance to intergranular corrosion is required.

• Excellent for fillet and downhand welding. • Used for high-temperature service for welding Titanium

and Niobium stabilized stainless steels

Typical all weld metal composition [wt%]

• Weldable on both AC and DC

C Mn Si Cr Ni

0.025 0.80 0.80 19.50 10.3 Typical all weld metal composition [wt%]

Typical all weld metal mechanical properties C Mn Si Cr Ni

0.05 1.0 0.80 20.0 10.0

Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V]

580 450 40 35J@-105°C Typical all weld metal mechanical properties

Welding position Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V]

580 440 40 70J@20°C

Welding position

ASME: 1G 2F

ISO 6947 PA PB

Materials to be welded Current ASME: 1G 2F 2G 3G 4G

)= +( ~ Uo : 70v ISO 6947 PA PB PC PF PE

Extra low DIN 17 440 X2 CrNi 19 11

carbon 1.4311 Materials to be welded Current

C<0.03% /17 445 X2 CrNiN 18 10 Re-drying )= +( ~ Uo : 50v

Medium DIN 17 440 X5 CrNi 18 10 1.4301 2h/300ºC Medium DIN 17 440 X5 CrNi 18 10 1.4301

carbon /17 445 G-X6 CrNi 18 9 1.4308 carbon steels /17 445 G-X6 CrNi 18 9 1.4308 Re-drying

C>0.03% 2h/300ºC

X6 CrNiTi 18 10 1.4541 Ti-, Nb DIN 17 440 X6 CrNiTi 18 10 1.4541

Ti-, Nb DIN 17 440 Stabilized /17 445 X6 CrNiNb 18 10 1.4550

Stabilized /17 445 X6 CrNiNb 18 10 1.4550

G-X5 CrNiNb 18 9 1.4552

Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

1/16 1.6 12 300 24-40 0.5 1.5 9.0

Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg( 5/64 2.0 12 300 30-50 1.1 1.5 9.0

3/32 2.5 12 300 75-95 2.5 4.0 12.0 3/32 2.5 12 300 50-75 1.7 1.5 9.0

1/8 3.25 14/18 350/450 110-130 5.0/6.40 5.0/6.0 15.0/18.0 1/8 3.25 14 350 75-110 3.3 2.0 12.0

5/32 4.0 18 450 135-155 9.3 6.0 18.0 5/32 4.0 14 350 110-150 4.9 2.0 12.0

3/16 5.0 18 450 180-210 14.3 6.0 18.0 3/16 5.0 14 350 140-190 7.1 2.0 12.0

74 75