Page 34 - Technical Guidbook - Zika industrial Welding Supplies

P. 34

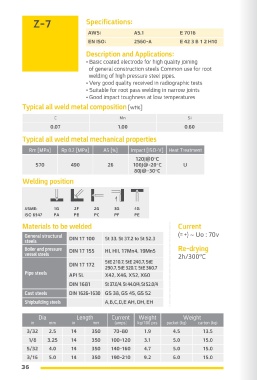

Z-7 Specifications: Specifications: Z-DIALOGUE

AWS: A5.1 E 7016 AWS: A5.1 E 7016

EN ISO: 2560-A E 42 3 B 1 2 H10 EN ISO: 2560-A E 42 3 B 1 2 H10

Description and Applications: Description and Applications:

• Basic coated electrode for high quality joining • Double coated basic electrode

of general construction steels Common use for root • Suitable for repair and maintenance work

welding of high pressure steel pipes. • Excellent for root pass and all positional welding

• Very good quality received in radiographic tests • High impact toughness at low temperatures

• Suitable for root pass welding in narrow joints Typical all weld metal composition [wt%]

• Good impact toughness at low temperatures

C Mn Si

Typical all weld metal composition [wt%]

0.06 1.10 0.65

C Mn Si

Typical all weld metal mechanical properties

0.07 1.00 0.60

Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment

Typical all weld metal mechanical properties

530 420 30 110J@-20°C U

Rm [MPa] Rp 0.2 [MPa] A5 [%] Impact [ISO-V] Heat Treatment 100J@-30°C

120J@0°C Welding position

570 490 26 100J@-20°C U

80J@-30°C

Welding position

ASME: 1G 2F 2G 3G 4G

ISO 6947 PA PB PC PF PE

Materials to be welded

ASME: 1G 2F 2G 3G 4G General structural Current

ISO 6947 PA PB PC PF PE steels DIN 17 100 St 33, St 37.2 to St 52.3 )= +( ~ Uo : 70v

Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5

Materials to be welded Current vessel steels Re-drying

General structural DIN 17 100 St 33, St 37.2 to St 52.3 )= +( ~ Uo : 70v DIN 17 172 StE 210.7, StE 240.7, StE

steels 290.7, StE 320.7 StE 360.7 2h/300ºC

Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5 Re-drying Pipe steels API 5L X42, X46, X52, X60

vessel steels 2h/300ºC DIN 1626-1630 St 37.0/4, St 44.0/4, St 52.0/4

StE 210.7, StE 240.7, StE

DIN 17 172 Cast steels DIN 1681 GS 38, GS 45, GS 52

290.7, StE 320.7, StE 360.7

Pipe steels API 5L X42, X46, X52, X60 Elevated temperature

steels DIN 17 175 St 35.8, St 45.8

DIN 1681 St 37.0/4, St 44.0/4, St 52.0/4

Fine grained steels DIN 17 102 StE 255 to StE 420

Cast steels DIN 1626-1630 GS 38, GS 45, GS 52

Shipbuilding steels A,B,C,D,E AH, DH, EH

Shipbuilding steels A,B,C,D,E AH, DH, EH

Dia Length Current Weight Weight Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg( in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

3/32 2.5 14 350 70-80 1.9 4.5 13.5 3/32 2.5 14 350 60-90 2.0 4.5 13.5

1/8 3.25 14 350 100-120 3.1 5.0 15.0 1/8 3.25 14/18 350/450 95-150 3.4/4.3 4.5 13.5

5/32 4.0 14 350 140-160 4.7 5.0 15.0 5/32 4.0 14/18 350/450 140-190 6.7 5.0/6.0 15.0/18.0

3/16 5.0 14 350 190-210 9.2 6.0 15.0 3/16 5.0 18 450 190-250 10.0 6.0 18.0

36 37