Page 29 - Technical Guidbook - Zika industrial Welding Supplies

P. 29

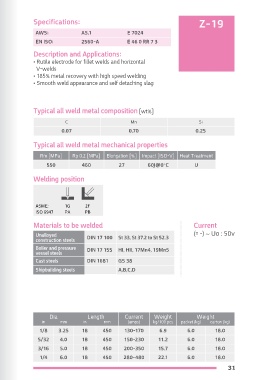

Z-18 Specifications: Specifications: Z-19

AWS: A5.1 E 7024 AWS: A5.1 E 7024

EN ISO: 2560-A E 46 0 RR 7 3 EN ISO: 2560-A E 46 0 RR 7 3

Description and Applications: Description and Applications:

• Rutile electrode for fillet welds and horizontal • Rutile electrode for fillet welds and horizontal

V-welds V-welds

• 165% metal recovery with high speed welding • 185% metal recovery with high speed welding

• Smooth weld appearance and self detaching slag • Smooth weld appearance and self detaching slag

Suitable for welding of tick and middle thick sheets in

flat position

Typical all weld metal composition [wt%] Typical all weld metal composition [wt%]

C Mn Si C Mn Si

0.07 0.70 0.25 0.07 0.70 0.25

Typical all weld metal mechanical properties Typical all weld metal mechanical properties

Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V] Heat Treatment Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V] Heat Treatment

550 480 26 60J@0°C U 550 460 27 60J@0°C U

Welding position Welding position

ASME: 1G 2F ASME: 1G 2F

ISO 6947 PA PB ISO 6947 PA PB

Materials to be welded Current Materials to be welded Current

Unalloyed DIN 17 100 St 33, St 37.2 to St 52.3 )= -( ~ Uo : 50v Unalloyed DIN 17 100 St 33, St 37.2 to St 52.3 )= -( ~ Uo : 50v

construction steels construction steels

Boiler and pressure DIN 17 155 HI, HII, 17Mn4 Boiler and pressure DIN 17 155 HI, HII, 17Mn4, 19Mn5

vessel steels vessel steels

Cast steels DIN 1681 GS 38 Cast steels DIN 1681 GS 38

Shipbuilding steels A,B,C,D Shipbuilding steels A,B,C,D

Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

Dia Length Current Weight Weight

3/32 3.25 14 350 85-125 3.0 4.5 13.5 in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

1/8 3.25 18 450 130-175 6.5 6.0 18.0 1/8 3.25 18 450 130-170 6.9 6.0 18.0

5/32 4.0 18 450 150-240 10.0 6.0 18.0 5/32 4.0 18 450 150-230 11.2 6.0 18.0

3/16 5.0 18 450 210-290 15.0 6.0 18.0 3/16 5.0 18 450 200-350 15.7 6.0 18.0

1/4 6.0 18 450 290-420 19.5 6.0 18.0 1/4 6.0 18 450 280-480 22.1 6.0 18.0

30 31