Page 17 - Technical Guidbook - Zika industrial Welding Supplies

P. 17

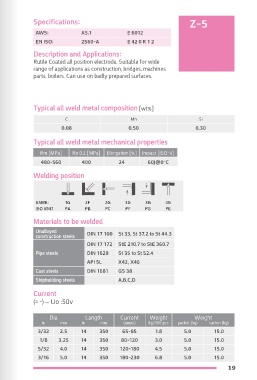

Z-910 Specifications: Specifications: Z-5

AWS: A5.5 E 9010-G AWS: A5.1 E 6012

EN ISO: 2560-A E 50 0 C Z 1 EN ISO: 2560-A E 42 0 R 1 2

Description and Applications: Description and Applications:

• Electrode with cellulose coating for general welding Rutile Coated all position electrode. Suitable for wide

purposes. range of applications as construction, bridges, machines

• Good welding performance in vertical down position. parts, boilers. Can use on badly prepared surfaces.

• Suitable for welding pipes, pressure vessels,

with high strength, also suitable for hot pass welding,

filler and cover lines.

Typical all weld metal composition [wt%] Typical all weld metal composition [wt%]

C Mn Si Mo Ni C Mn Si

0.11 1.1 0.55 0.23 0.62 0.08 0.50 0.30

Typical all weld metal mechanical properties Typical all weld metal mechanical properties

Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V] Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V]

616 690 21 79J@0°C 480-560 400 24 60J@0°C

Welding position Welding position

ASME: 1G 2F 2G 3G 3G 4G ASME: 1G 2F 2G 3G 3G 4G

ISO 6947 PA PB PC PF PG PE ISO 6947 PA PB PC PF PG PE

Materials to be welded Materials to be welded

Unalloyed

API Spec 5L: X65, X70 construction steels DIN 17 100 St 33, St 37.2 to St 44.3

DIN 17 172 StE 210.7 to StE 360.7

Current

)= +( Pipe steels DIN 1629 St 35 to St 52.4

API 5L X42, X46

Cast steels DIN 1681 GS 38

Shipbuilding steels A,B,C,D

Current

)= -( ~ Uo :50v

Dia Langth Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

Dia Langth Current Weight

in mm in mm )amps( packet )kg( carton )kg( 3/32 2.5 14 350 65-85 1.8 5.0 15.0

1/8 3.25 14 350 80-125 5.0 15.0 1/8 3.25 14 350 80-120 3.0 5.0 15.0

5/32 4.0 14 350 110-180 5.0 15.0 5/32 4.0 14 350 120-180 4.5 5.0 15.0

3/16 5.0 14 350 140-230 5.0 15.0 3/16 5.0 14 350 180-230 6.8 5.0 15.0

18 19