Page 21 - Technical Guidbook - Zika industrial Welding Supplies

P. 21

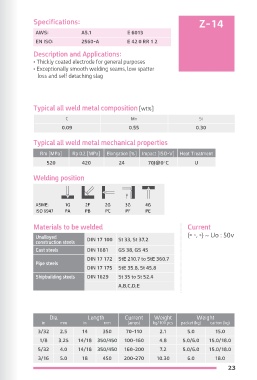

Z-11 Specifications: Specifications: Z-14

AWS: A5.1 E 6013 AWS: A5.1 E 6013

EN ISO: 2560-A E 42 0 RR 1 2 EN ISO: 2560-A E 42 0 RR 1 2

Description and Applications: Description and Applications:

• Electrode with rutile thick covering for all welding • Thickly coated electrode for general purposes

positions. • Exceptionally smooth welding seams, low spatter

• Suitable for welding of structures, pipes, vessels, loss and self detaching slag

machine parts.

• Very easy slag release and arc striking, low sputtering

and soft arc

Typical all weld metal composition [wt%] Typical all weld metal composition [wt%]

C Mn Si C Mn Si

0.08 0.50 0.30 0.09 0.55 0.30

Typical all weld metal mechanical properties Typical all weld metal mechanical properties

Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V] Heat Treatment Rm [MPa] Rp 0.2 [MPa] Elongation [%] Impact [ISO-V] Heat Treatment

520 440 26 70J@0°C U 520 420 24 70J@0°C U

Welding position Welding position

ASME: 1G 2F 2G 3G 4G ASME: 1G 2F 2G 3G 4G

ISO 6947 PA PB PC PF PE ISO 6947 PA PB PC PF PE

Materials to be welded Current Materials to be welded Current

Unalloyed DIN 17 100 St 33, St 37.2 (= -, +) ~ Uo : 50v Unalloyed DIN 17 100 St 33, St 37.2 (= -, +) ~ Uo : 50v

construction steels construction steels

DIN 17 172 StE 210.7 to StE 360.7 Cast steels DIN 1681 GS 38, GS 45

Pipe steels DIN 17 175 St 35.8 to St 45.8 DIN 17 172 StE 210.7 to StE 360.7

Pipe steels

DIN 1629 St 35 to St 52.4 DIN 17 175 StE 35.8, St 45.8

Cast steels DIN 1681 GS 38 Shipbuilding steels DIN 1629 St 35 to St 52.4

A,B,C,D,E

Dia Length Current Weight Weight

in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

Dia Length Current Weight Weight

5/64 2.0 12 300 50-70 1.1 4.0 12.0 in mm in mm )amps( kg/100 pcs packet )kg( carton )kg(

3/32 2.5 14 350 60-100 2.0 5.0 15.0 3/32 2.5 14 350 70-110 2.1 5.0 15.0

1/8 3.25 14/18 350/450 80-150 3.3/4.2 5.0/6.0 15.0/18.0 1/8 3.25 14/18 350/450 100-160 4.8 5.0/6.0 15.0/18.0

5/32 4.0 14/18 350/450 80-150 4.9/6.2 5.0/6.0 15.0/18.0 5/32 4.0 14/18 350/450 160-200 7.2 5.0/6.0 15.0/18.0

3/16 5.0 14/18 350/450 180-260 7.7/9.9 5.0/6.0 15.0/18.0 3/16 5.0 18 450 200-270 10.30 6.0 18.0

22 23