Page 22 - Product Catalog By Zika Welding

P. 22

22

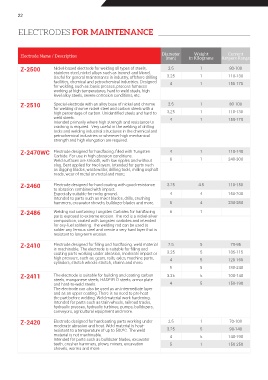

ELECTRODES FOR MAINTENANCE

Diameter Weight Current

Electrode Name / Description

(mm) in Kilograms Ampere Range

Z-2500 Nickel-based electrode for welding all types of steels, 2.5 1 80-100

stainless steel, nickel alloys such as Inconel and Monel.

Useful for general maintenance in industry, offshore drilling 3.25 1 110-130

facilities, chemical and petrochemical industries. Designed 4 1 150-170

for welding, such as: basic presses, process furnaces

working at high temperatures, hard to weld steels, high-

level alloy steels, severe corrosion conditions, etc.

Z-2510 Special electrode with an alloy base of nickel and chrome 2.5 1 80-100

for welding chrome-nickel steel and carbon steels with a

high percentage of carbon. Unidentified steels and hard-to- 3.25 1 110-130

weld steels. 4 1 150-170

Intended primarily where high strength and resistance to

cracking is required. Very useful in the welding of drilling

tools and welding industrial structures in the chemical and

petrochemical industries or wherever high mechanical

strength and high elongation are required.

Z-2470WC Electrode designed for hardfacing, filled with Tungsten 4 1 110-140

Carbide. For use in high abrasion conditions.

Weld surfaces are smooth, with low ripples and without 6 1 240-300

slag. Best applied for two layers. Intended for parts such

as digging blades, wastewater, drilling tools, milling asphalt

roads, wear of metal on metal and more.

Z-2460 Electrode designed for hard coating with good resistance 3.25 4.5 110-150

to abrasion combined with impact.

Especially suitable for rocky ground. 4 4 150-200

Intended to parts such as mixer blades, drills, crushing

hammers, excavator shovels, bulldozer blades and more. 5 4 230-280

Z-2486 Welding rod containing Tungsten Carbides for hardfacing 6 1

parts exposed to extreme erosion. The rod is a nickel-silver

composition, coated with tungsten carbides and intended

for oxy-fuel soldering. The welding rod can be used to

solder any ferrous steel and create a very hard layer that is

resistant to long-term erosion.

Z-2410 Electrode designed for filling and hardfacing. weld material 2.5 5 70-95

is machinable. The electrode is suitable for filling and

coating parts working under abrasion, moderate impact or 3.25 5 105-115

high pressure, such as: gears, rails, axles, machine parts, 4 5 120-160

cylinders, stretch wheels stretch, chains and more.

5 5 180-240

Z-2411 The electrode is suitable for building and coating carbon 3.25 5 100-140

steels, manganese steels, HADFIELD steels, armor plate

and hard-to-weld steels. 4 5 150-190

The electrode can also be used as an intermediate layer

and as an upper coating. There is no need to pre-heat

the part before welding. Weld material work hardening.

Intended for parts such as train wheels, railroad tracks,

hydraulic presses, hydraulic turbines, pumps, bulldozers,

conveyors, agricultural equipment and more.

Z-2420 Electrode designed for hardcoating parts working under 2.5 1 70-100

moderate abrasion and heat. Weld material is heat-

resistant to a temperature of up to 500ºC. The weld 3.25 5 90-140

material is not machinable. 4 5 140-190

Intended for parts such as bulldozer blades, excavator

teeth, crusher hammers, plows, mixers, excavation 5 1 150-250

shovels, worms and more.