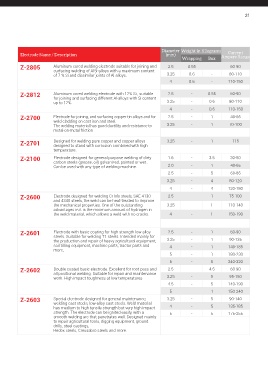

Page 21 - Product Catalog By Zika Welding

P. 21

21

Diameter Weight in Kilograms Current

Electrode Name / Description (mm) Ampere Range

Wrapping Box

Z-2805 Aluminum cored welding electrode suitable for joining and 2.5 0.55 - 60-90

surfacing welding of AlSi-alloys with a maximum content

of 7 % Si and dissimilar joints of Al-alloys. 3.25 0.6 - 80-110

4 0.6 - 110-150

Z-2812 Aluminum cored welding electrode with 12% Si , suitable 2.5 - 0.55 60-90

for joining and surfacing different Al-alloys with Si content

up to 12%. 3.25 - 0.6 80-110

4 - 0.6 110-150

Z-2700 Electrode for joining, and surfacing copper tin alloys and for 2.5 - 1 40-65

weld cladding on cast iron and steel.

The welding material has good ductility and resistance to 3.25 - 1 70-100

metal-on-metal friction

Z-2701 Designed for welding pure copper and copper alloys 3.25 - 1 115

designed to stand with corrosion combined with high

temperature .

Z-2100 Electrode designed for general purpose welding of dirty 1.6 - 3.5 30-50

carbon steels (grease, oil) galvanized, painted or wet..

Can be used with any type of welding machine. 2.0 - 1 40-65

2.5 - 5 60-85

3.25 - 4 80-120

4 - 4 120-180

Z-2600 Electrode designed for welding Cr-Mo steels, SAE 4130 2.5 - 1 75-100

and 4340 steels, the weld can be heat-treated to improve

the mechanical properties. One of the outstanding 3.25 - 1 110-140

advantages in it is the minimum amount of hydrogen in

the weld material, which allows a weld with no cracks. 4 - 1 150-190

Z-2601 Electrode with basic coating for high strength low alloy 2.5 - 1 60-90

steels. Suitable for welding T1 steels. Intended mainly for

the production and repair of heavy agricultural equipment, 3.25 - 1 90-135

soil tilling equipment, machine parts, tractor parts and 4 - 1 140-185

more.

5 - 1 180-230

6 - 5 240-320

Z-2602 Double coated basic electrode. Excellent for root pass and 2.5 - 4.5 60-90

all positional welding. Suitable for repair and maintenance

work. High impact toughness at low temperatures 3.25 - 5 95-150

4.5 - 5 140-190

5 - 1 150-240

Z-2603 Special electrode designed for general maintenance, 3.25 - 5 90-140

welding cast steels, low-alloy cast steels. Weld material

has medium to high tensile strength but very high impact 4 - 5 135-185

strength. The electrode can be ignited easily, with a 5 - 5 175-255

smooth welding arc that penetrates well. Designed mainly

to repair agricultural tools, digging equipment, ground

drills, steel castings,

Redox steels, Creusabro steels and more.