Page 16 - Product Catalog By Zika Welding

P. 16

16

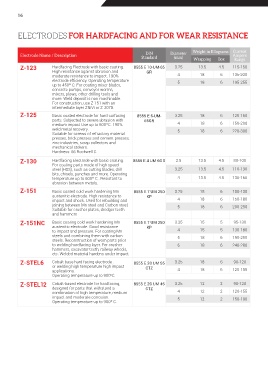

ELECTRODES FOR HARDFACING AND FOR WEAR RESISTANCE

DIN

Ampere

Electrode Name / Description Standard Diameter Weight in Kilograms Current

(mm)

Box

Wrapping

Range

Z-123 Hardfacing Electrode with basic coating. 8555 E 10-UM-65 3.25 13.5 4.5 115-150

High resistance against abrasion and GR

moderate resistance to impact. 190% 4 18 6 135-200

electrode efficiency. Operating temperature 5 18 6 195-255

up to 450º C. For coating mixer blades,

concrete pumps, conveyor worms,

mixers, plows, other drilling tools and

more. Weld deposit is non-machinable.

For construction, use Z-151 with an

intermediate layer ZNiVi or Z-307B.

Z-125 Basic coated electrode for hard surfacing 8555 E 6-UM- 3.25 18 6 125-160

parts. Subjected to severe abrasion with 65GR

medium impact Use up to 600ºC. 190% 4 18 6 150-200

weld metal recovery. 5 18 6 220-300

Suitable for screws of refractory material

presses, brick presses and cement presses,

zinc industries, scrap collectors and

mechanical stokers.

Hardness: 66 Rockwell C.

Z-130 Hardfacing Electrode with basic coating. 8555 E 4 UM 60 S 2.5 13.5 4.5 80-100

For coating parts made of high speed

steel (HSS), such as cutting blades, drill 3.25 13.5 4.5 110-130

bits, chisels, punches and more. Operating

temperature up to 600º C . Resistant to 4 13.5 4.5 130-160

abrasion between metals.

Z-151 Basic coated cold work hardening Mn 8555 E 7 UM 250 3.25 18 6 100-130

austenitic electrode. High resistance to KP

impact and shock. Used for rebuilding and 4 18 6 150-180

joining between Mn steel and Carbon steel. 5 18 6 200-250

Suitable for crusher plates, dredger teeth

and hammers

Z-151NC Basic coating cold work hardening Mn 8555 E 7 UM 250 3.25 15 5 95-130

austenitic electrode. Good resistance KP

to impact and pressure. For coating Mn 4 15 5 130-180

steels and combining them with carbon 5 18 6 190-250

steels. Reconstruction of worn parts prior

to welding hardfacing layer. For crusher 6 18 6 240-280

hammers, excavator teeth, railway wheels,

etc. Welded material hardens under impact.

Z-STEL6 Cobalt base hard facing electrode . 8555 E 20 UM 55 3.25 18 6 90-120

or welding high temperature high impact CTZ

applications. 4 18 6 120-155

Operating temperature up to 900 C.

o

Z-STEL12 Cobalt-based electrode for hardfacing, 8555 E 20 UM 45 3.25 12 2 90-120

designed for parts that withstand a CTZ

combination of high temperature, medium 4 12 2 120-155

impact and moderate corrosion. 5 12 2 150-190

Operating temperature up to 900º C.