Page 19 - Product Catalog By Zika Welding

P. 19

19

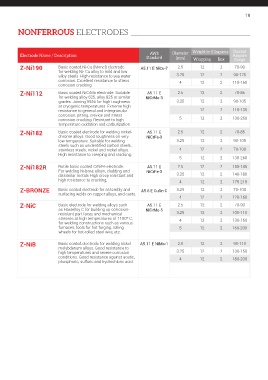

NONFERROUS ELECTRODES

Ampere

Electrode Name / Description AWS Diameter Weight in Kilograms Current

Standard (mm) Wrapping Box Range

Z-Ni190 Basic coated Ni-Cu (Monel) electrode A5.11 E NiCu-7 2.5 12 2 70-90

for welding Ni- Cu alloy to mild and low

alloy steels. High resistance to sea water 3.25 12 2 90-125

corrosion. Excellent resistance to stress 4 12 2 110-160

corrosion cracking.

Z-Ni112 Basic coated NiCrMo electrode. Suitable A5.11 E 2.5 12 2 70-85

for welding alloy 625, alloy 825 or similar NiCrMo-3

grades. Joining 9%Ni for high toughness 3.25 12 2 90-105

at cryogenic temperatures. Extreme high

resistance to general and intergranular 12 2 115-135

corrosion, pitting, crevice and stress

corrosion cracking. Resistant to high 5 12 2 130-260

temperature oxidation and carburization

Z-Ni182 Basic coated electrode for welding nickel- A5.11 E 2.5 12 2 70-85

chrome alloys. Good toughness on very NiCrFe-3

low temperature. Suitable for welding 3.25 12 2 90-105

steels such as unidentified carbon steels,

stainless steels, nickel and nickel alloys. 4 12 2 70-100

High resistance to creeping and cracking.

5 12 2 130-260

Z-Ni182R Rutile basic coated CrNiFe electrode. A5.11 E 2.5 12 2 105-145

For welding Ni-base alloys, cladding and NiCrFe-3

dissimilar metals High creep resistant and 3.25 12 2 140-180

high resistance to cracking. 4 12 2 175-215

Z-BRONZE Basic coated electrode for assembly and A5.6 E CuSn-C 3.25 12 2 70-100

surfacing welds on copper alloys, and casts.

4 12 2 120-160

Z-NiC Basic electrode for welding alloys such A5.11 E 2.5 12 2 70-90

as Hastelloy C for building up corrosion- NiCrMo-5

resistant part faces and mechanical 3.25 12 2 100-110

stresses at high temperatures of 1100º C, 4 12 2 130-160

for welding constructions such as various

furnaces, tools for hot forging, rolling 5 12 2 160-200

wheels for hot-rolled steel wire, etc.

Z-NiB Basic coated electrode for welding nickel A5.11 E NiMo-1 2.5 12 2 90-110

molybdenum alloys. Good resistance to

high temperatures and severe corrosion 3.25 12 2 130-150

conditions. Good resistance against acetic, 4 12 2 180-200

phosphoric, sulfuric and hydrochloric acid.