Page 20 - Product Catalog By Zika Welding

P. 20

20

ELECTRODES FOR MAINTENANCE

Maintenance electrodes from the Z-2000 series are the fruit of research and development conducted

at the Zika plant.

These electrodes are designed for maintenance, with regard to market needs overall and customer

requirements in particular. These electrodes from the Z-2000 series have a higher quality than that

of the base metal, thanks to the ongoing research that Zika conducts in its R&D department, which

stands at a very high technical level.

The Z-2000 series electrodes have good penetration and strong mechanical characteristics and are

designed, among other things, for welding iron and galvanized sheet metal, pipes and wet and dirty

surfaces, red copper, gouging and perforating metals, welding gray metals and repairing heavy work tools.

In light of the increasing use of maintenance electrodes and requests from customers, Zika has

published a special technical guide for maintenance electrode use.

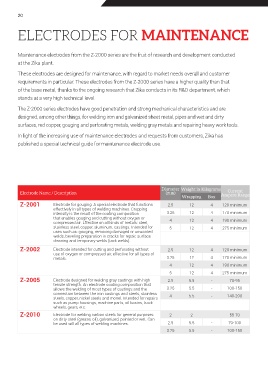

Diameter Weight in Kilograms Current

Electrode Name / Description (mm) Ampere Range

Wrapping Box

Z-2001 Electrode for gouging. A special electrode that functions 2.5 12 4 120 minimum

effectively in all types of welding machines. Cropping

intensity is the result of the coating composition 3.25 12 4 170 minimum

that enables gouging and cutting without oxygen or 4 12 4 190 minimum

compressed air. Effective on all kinds of metals: steel,

stainless steel, copper, aluminum, castings. Intended for 5 12 4 275 minimum

uses such as: gouging, removing damaged or unwanted

welds, beveling preparation in cracks for repair, surface

cleaning and temporary welds (tack welds).

Z-2002 Electrode intended for cutting and perforating without 2.5 12 4 120 minimum

use of oxygen or compressed air, effective for all types of

metals. 3.25 12 4 170 minimum

4 12 4 190 minimum

5 12 4 275 minimum

Z-2005 Electrode designed for welding gray castings with high 2.5 5.5 - 70-95

tensile strength. An electrode coating composition that

allows the welding of most types of castings and the 3.25 5.5 - 100-150

connection between the iron castings and steels, stainless 4 5.5 - 140-200

steels, copper, nickel steels and monel. Intended for repairs

such as pump housings, machine parts, oil basins, track

wheels, gears, etc.

Z-2010 Electrode for welding carbon steels for general purposes 2 2 - 55-70

on dirty steel (grease, oil), galvanized, painted or wet. Can

be used will all types of welding machines. 2.5 5.5 - 70-100

3.25 5.5 - 100-150