Page 15 - Product Catalog By Zika Welding

P. 15

15

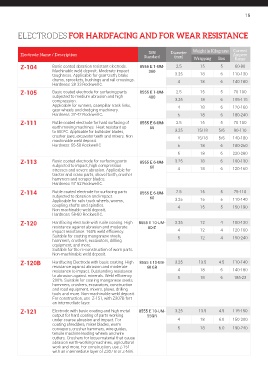

ELECTRODES FOR HARDFACING AND FOR WEAR RESISTANCE

DIN Diameter Weight in Kilograms Current

Electrode Name / Description Ampere

Standard (mm) Wrapping Box Range

Z-104 Basic coated abrasion resistant electrode. 8555 E 1-UM- 2.5 15 5 60-80

Machinable weld deposit. Moderate impact 300

toughness. Applicable for gear teeth, brake 3.25 18 6 110-130

drums, sprockets, bushings and rail crossings. 4 18 6 140-180

Hardness: 28-33 Rockwell C.

Z-105 Basic coated electrode for surfacing parts 8555 E 1-UM- 2.5 15 5 70-100

subjected to medium abrasion and high 400

compression. 3.25 18 6 105-115

Applicable for runners, caterpillar track links, 4 18 6 120-160

gear wheels and dredging machinery.

Hardness: 37-42 Rockwell C. 5 18 6 180-240

Z-111 Rutile coated electrode for hard surfacing of 8555 E 6-UM- 2.5 15 5 70-100

earth moving machines. Heat resistant up 55

to 600ºC. Applicable for bulldozer blades, 3.25 15/18 5/6 90-110

crusher jaws, excavator teeth and mixers. Non 4 15/18 5/6 140-180

machinable weld deposit.

Hardness: 55-58 Rockwell C 5 18 6 180-250

6 18 6 220-280

Z-113 Basic coated electrode for surfacing parts 8555 E 6-UM- 3.25 18 6 100-130

subjected to impact, high compression 60

stresses and severe abrasion. Applicable for 4 18 6 120-160

tractor and crane parts, shovel teeth, crusher

hammers and scraper blades.

Hardness: 57-62 Rockwell C.

Z-114 Rutile coated electrode for surfacing parts 8555 E 6-UM- 2.5 15 5 75-110

subjected to abrasion and impact. 60

Applicable for rails truck wheels, worms, 3.25 15 5 110-140

coupling shafts and spindles. 4 15 5 150-190

Non machinable weld deposit.

Hardness: 58-60 Rockwell C.

Z-120 Hardfacing electrode with rutile coating. High 8555 E 10-UM- 3.25 12 4 100-130

resistance against abrasion and moderate 60-Z

impact resistance. 160% weld efficiency. 4 12 4 120-160

Suitable for coating manganese steels, 5 12 4 150-240

hammers, crushers, excavators, drilling

equipment, and more.

Suitable for the re-construction of worn parts.

Non-machinable weld deposit.

Z-120B Hardfacing Electrode with basic coating. High 8555 E 10-UM- 3.25 13.5 4.5 110-140

resistance against abrasion and moderate 60 GR

resistance to impact. Outstanding resistance 4 18 6 140-180

to abrasion against minerals. Weld efficiency 5 18 6 185-23

200%. Suitable for coating manganese steels,

hammers, crushers, excavators, construction

and road equipment, mixers, plows, drilling

tools and more. Non-machinable weld deposit.

For construction, use Z-151, with Z307B fort

an intermediate layer.

Z-121 Electrode with basic coating and high metal 8555 E 10-UM- 3.25 13.5 4.5 115-150

output for hard coating of parts working 55GR

under coarse abrasion and impact. For 4 18 6.0 150-200

coating shredders, mixer blades, worm

conveyors, crusher hammers, wire guides, 5 18 6.0 190-240

tensile machine leading wheels and wire

cutters. Crushers for loose material that cause

abrasion earth-working machines, agricultural

work and more. For construction, use Z-151

with an intermediate layer of Z307 B or Z-NiVi.