Page 12 - Product Catalog By Zika Welding

P. 12

12

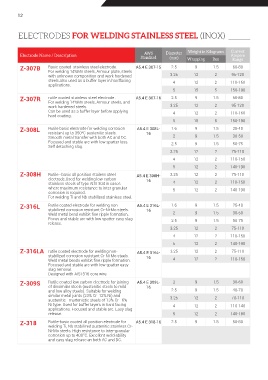

ELECTRODES FOR WELDING STAINLESS STEEL (INOX)

Weight in Kilograms

AWS

Electrode Name / Description Standard Diameter Wrapping Box Current

Ampere

(mm)

Range

Z-307B Basic coated stainless steel electrode. A5.4 E 307-15 2.5 9 1.5 60-80

For welding 14%Mn steels, Armour plate, steels

with unknown composition and work hardened 3.25 12 2 95-120

steels.also used as a buffer layer in hardfacing 4 12 2 110-160

applications.

5 15 5 150-190

Z-307R rutile coated stainless steel electrode . A5.4 E 307-16 2.5 9 1.5 65-80

For welding 14%Mn steels, Armour steels, and

work hardened steels. 3.25 12 2 95-120

Can be used as a buffer layer before applying 4 12 2 110-160

hard coating.

5 15 5 150-190

Z-308L Rutile basic electrode for welding corrosion A5.4 E 308L- 1.6 9 1.5 25-40

resistant up to 350 C austenitic steels. 16

o

Smooth metal transfer with both AC and DC. 2 9 1.5 30-50

Focused and stable arc with low spatter loss. 2.5 9 1.5 50-75

Self detaching slag.

3.25 12 2 75-110

4 12 2 110-150

5 12 2 140-190

Z-308H Rutile - basic all position stailess steel A5.4 E 308H- 3.25 12 2 75-110

electrode.Used for welding low carbon 16

stainless steels of type AISI 304 in cases 4 12 2 110-150

where maximum resistance to inter granular 5 12 2 140-190

corrosion is required.

For welding Ti and Nb stabilized stainless steel.

Z-316L Rutile coated electrode for welding non A5.4 E 316L- 1.6 9 1.5 25-40

stabilized corrosion resistant Cr-Ni-Mo steels. 16

Weld metal bead exhibit fine ripple formation. 2 9 1.5 30-50

Focus and stable arc with low spatter easy slag 2.5 9 1.5 50-75

release.

3.25 12 2 75-110

4 12 2 110-150

5 12 2 140-190

Z-316LA rutile coated electrode for welding non- A5.4 E 316L- 3.25 12 2 75-110

stabilized corrosion resistant Cr-Ni-Mo steels. 16

Weld metal beads exhibit fine ripple formation. 4 12 2 110-150

Focused and stable arc with low spatter easy

slag removal.

Designed with AISI 316 core wire.

Z-309S Rutile coated low carbon electrode for joining A5.4 E 309L- 2 9 1.5 30-60

of dissimilar steels (austenitic steels to mild 16

and low alloy steels). Suitable for welding 2.5 9 1.5 40-70

similar metal joints (23% Cr- 12% Ni) and 3.25 12 2 70-110

austenitic - martenistic steels of 13% Cr - 6%

Ni type. Used for buffer layers in hard facing 4 12 2 110-140

applications. Focused and stable arc. Easy slag

release. 5 12 2 140-180

Z-318 Rutile-basic coated all position electrode for A5.4 E 318-16 2.5 9 1.5 50-80

welding Ti, Nb stabilized austenitic stainless Cr-

Ni-Mo steels. High resistance to inter-granular

corrosion up to 400°C. Excellent weld-ability

and easy slag release an both AC and DC.