Page 10 - Product Catalog By Zika Welding

P. 10

10

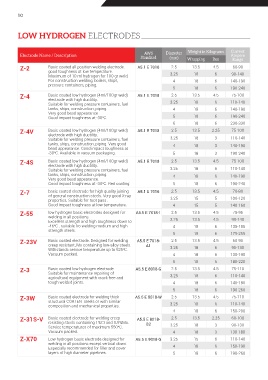

LOW HYDROGEN ELECTRODES

Weight in Kilograms

AWS

Electrode Name / Description Standard Diameter Wrapping Box Current

Ampere

(mm)

Range

Z-2 Basic coated all position welding electrode. A5.1 E 7018 2.5 13.5 4.5 60-90

good toughness at low temperature.

Maximum of 10 ml hydrogen for 100 gr weld. 3.25 18 6 90-140

For construction welding, boilers, ships, 4 18 6 140-190

pressure containers, piping.

5 18 6 190-240

Z-4 Basic coated low hydrogen (4ml/100gr weld) A5.1 E 7018 2.5 13.5 4.5 75-100

electrode with high ductility. 3.25 18 6 110-140

Suitable for welding pressure containers, fuel

tanks, ships, construction, piping. 4 18 6 140-190

Very good bead appearance

Good impact toughness at -30 C. 5 18 6 190-240

o

6 18 6 230-330

Z-4V Basic coated low hydrogen (4ml/100gr weld) A5.1 E 7018 2.5 13.5 2.25 75-100

electrode with high ductility.

Suitable for welding pressure containers, fuel 3.25 18 3 110-140

tanks, ships, construction, piping. Very good 4 18 3 140-190

bead appearance. Good impact toughness at

-30 C. Available in vacuum packaging. 5 18 3 190-240

o

Z-4S Basic coated low hydrogen (4ml/100gr weld) A5.1 E 7018 2.5 13.5 4.5 75-100

electrode with high ductility.

Suitable for welding pressure containers, fuel 3.25 18 6 110-140

tanks, ships, construction, piping. 4 18 6 140-190

Very good bead appearance.

Good impact toughness at -30 C. Red coating. 5 18 6 190-240

o

Z-7 basic coated electrode for high quality joining A5.1 E 7016 2.5 13.5 4.5 70-80

of general construction steels. Very good X-ray 3.25 15 5 100-120

properties. Suitable for root pass .

Good impact toughness at low temperature. 4 15 5 140-160

Z-55 low hydrogen basic electrodes designed for A5.5 E 7018-1 2.5 13.5 4.5 75-95

welding in all positions.

Excellent strength and high toughness down to 3.25 13.5 4.5 90-140

-46 C . suitable fro welding medium and high 4 18 6 135-185

o

strength steels.

5 18 6 175-255

Z-23V Basic coated electrode. Designed for welding A5.5 E 7018- 2.5 13.5 4.5 60-90

creep resistant, Mo containing low-alloy steels. A1 3.25 18 6 90-130

Withstands service temperature up to 525 C.

o

Vacuum-packed. 4 18 6 130-190

5 18 6 180-220

Z-3 Basic coated low hydrogen electrode A5.5 E 8018-G 2.5 13.5 4.5 75-110

Suitable for maintenance repairing of

agricultural equipment with crack free and 3.25 18 6 110-140

tough welded joints. 4 18 6 140-180

5 18 6 190-260

Z-3W Basic coated electrode for welding thick A5.5 E 8018-W 2.5 13.5 4.5 75-110

structural CORTEN steels or with similar

composition and mechanical properties. 3.25 18 6 110-140

4 18 6 150-200

Z-31S-V Basic coated electrode for welding creep A5.5 E 8018- 2.5 13.5 2.25 60-100

resisting steels containing 1%Cr and 0.5%Mo. B2

Service temperatures of maximum 550 C. 3.25 18 3 90-130

o

Vacuum packed. 4 18 3 130-180

Z-X70 Low hydrogen basic electrode designed for A5.5 E 9018-G 3.25 15 6 110-140

welding in all positions except vertical down.

Especially recommended for filler and cover 4 18 6 150-190

layers of high diameter pipelines. 5 18 6 190-260