Page 13 - Product Catalog By Zika Welding

P. 13

13

Current

Weight in Kilograms

AWS

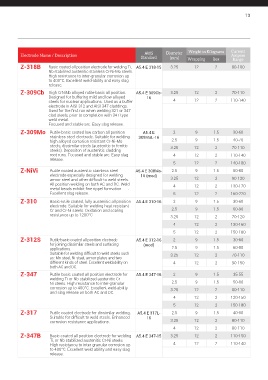

Electrode Name / Description Standard Diameter Wrapping Box Ampere

(mm)

Range

Z-318B Basic coated all position electrode for welding Ti, A5.4 E 318-15 3.25 12 2 80-100

Nb stabilized austenitic stainless Cr-Ni-Mo steels.

High resistance to inter-granular corrosion up

to 400°C. Excellent weld-ability and easy slag

release.

Z-309Cb High CrNiNb alloyed rutile-basic all position. A5.4 E 309Cb- 3.25 12 2 70-110

Designed for buffering mild and low alloyed 16

steels for nuclear applications. Used as a buffer 4 12 2 110-140

electrode in AISI 312 and AISI 347 claddings.

Used for the first run when welding 321 or 347

clad steels, prior to completion with 347 type

weld metal.

Focused and stable arc. Easy slag release.

Z-309Mo Rutile-basic coated low carbon all position A5.4 E 2 9 1.5 30-60

stainless steel electrode. Suitable for welding 309MoL-16

high alloyed corrosion resistant Cr-Ni-Mo 2.5 9 1.5 40-70

steels, dissimilar steels (austenitic to ferritic 3.25 12 2 70-110

steels). Depositon of austenitic cladding

root runs. Focused and stable arc. Easy slag 4 12 2 110-140

release.

5 12 2 140-180

Z-NiVi Rutile coated austenitic stainless steel A5.4 E 308Mo- 2.5 9 1.5 50-80

electrode especially designed for welding 16 (mod)

armor steel and other difficult to weld steels. 3.25 12 2 90-120

All position welding on both AC and DC. Weld 4 12 2 130-170

metal beads exhibit fine rippel formation .

Excellent slag release. 5 12 2 160-220

Z-310 Basic-rutile coated, fully austenitic all position A5.4 E 310-16 2 9 1.5 30-60

electrode. Suitable for welding heat resistant

Cr and Cr-Ni steels. Oxidation and scaling 2.5 9 1.5 60-90

resistance up to 1200°C 3.25 12 2 70-120

4 12 2 130-160

5 12 2 150-180

Z-312S Rutile-basic coated all position electrode A5.4 E 312-16 2 9 1.5 30-60

for joining dissimilar steels and surfacing (mod)

applications. 2.5 9 1.5 60-80

Suitable for welding difficult to weld steels such 3.25 12 2 70-110

as: Mn-steel, Ni-steel, armor plates and two

different kinds of steel. Excellent weldability on 4 12 2 90-150

both AC and DC.

Z-347 Rutile-basic coated all position electrode for A5.4 E 347-16 2 9 1.5 35-55

welding Ti or Nb stabilized austenitic Cr-

Ni steels. High resistance to inter-granular 2.5 9 1.5 50-80

corrosion up to 400°C. Excellent weld-ability 3.25 12 2 80-110

and slag release an both AC and DC.

4 12 2 120-150

5 12 2 150-180

Z-317 Rutile coated electrode for dissimilar welding. A5.4 E 317L- 2.5 9 1.5 40-80

Suitable for difficult to weld steels. Enhanced 16

corrosion resistance applications. 3.25 12 2 80-110

4 12 2 80-110

Z-347B Basic coated all position electrode for welding A5.4 E 347-15 3.25 12 2 110-150

Ti, or Nb stabilized austenitic Cr-Ni steels.

High resistance to inter-granular corrosion up 4 12 2 110-140

to 400°C. Excellent weld-ability and easy slag

release.