Page 11 - Product Catalog By Zika Welding

P. 11

11

Weight in Kilograms

AWS

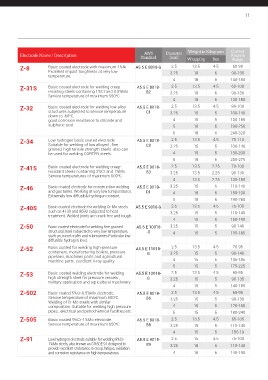

Electrode Name / Description Standard Diameter Wrapping Box Current

Ampere

(mm)

Range

Z-8 Basic coated electrode with maximum 1%Ni. A5.5 E 8018-G 2.5 13.5 4.5 60-90

Excellent impact toughness at very low 3.25 18 6 90-135

temperature.

4 18 6 140-180

Z-31S Basic coated electrode for welding creep A5.5 E 8018- 2.5 13.5 4.5 60-100

resisting steels containing 1%Cr and 0.5%Mo B2 3.25 18 6 90-130

Service temperature of maximum 550 C.

o

4 18 6 130-180

Z-32 Basic coated electrode for welding low alloy A5.5 E 8018- 2.5 13.5 4.5 80-100

structures subjected to service temperature C1 3.25 15 5 100-140

down to -60 C.

o

good corrosion resistance to chloride and 4 15 5 130-185

sulphuric acid. 5 18 6 190-250

6 18 6 240-320

Z-34 Low hydrogen basic coated electrode. A5.5 E 8018- 2.5 13.5 4.5 75-110

Suitable for welding of low alloyed , fine C3 3.25 15 5 100-140

grained, high tensile strength steels. also can

be used for welding CORTEN steels. 4 15 5 130-200

5 18 6 200-275

Z-41S Basic coated electrode for welding creep- A5.5 E 9018- 2.5 13.5 2.25 70-100

resistant steels containing 2%Cr and 1%Mo. B3 3.25 13.5 2.25 90-130

Service temperatures of maximum 600 C

o

4 13.5 2.25 130-180

Z-46 Basic coated electrode for construction welding A5.5 E 9018- 3.25 15 6 110-140

and gas tanks. Working at very low temperatures. D1 4 18 6 150-190

Extremely low diffusible hydrogen content.

5 18 6 190-260

Z-40S Basic coated electrode for welding Cr Mo steels A5.5 E 9018-G 2.5 13.5 4.5 75-100

such as 4130 and 8630 subjected to heat

treatment. Welded joints are crack free and tough. 3.25 15 5 110-140

4 15 5 150-190

Z-50 Basic coated electrode for welding fine grained A5.5 E 10018 3.25 15 5 90-140

structural steel subjected to very low temperature, -G 4 15 5 135-185

such as, navel crafts and submarines.Particular low

diffusible hydrogen level.

Z-52 Basic coated for welding high-pressure A5.5 E 11018- 2.5 13.5 4.5 70-95

containers, manufacturing boilers, pressure G 3.25 15 5 90-140

pipelines, machines parts and agricultural

machine parts. excellent X-ray quality 4 15 5 135-185

5 15 5 175-225

Z-53 Basic coated welding electrode for welding A5.5 E 12018- 2.5 13.5 4.5 65-95

high strength steel for pressure vessels , G 3.25 15 5 90-135

military application and agricultural machinery.

4 15 5 140-185

Z-502 Basic coated 5%Cr-0.5%Mo electrode. A5.5 E 8018- 2.5 13.5 4.5 65-95

o

Service temperature of maximum 600 C. B6 3.25 15 5 90-130

Welding of Cr-Mo steels with similar

composition. Suitable for welding high pressure 4 15 5 125-180

pipes , electrical and petrochemical facilities etc. 5 15 5 180-240

Z-505 Basic coated 9%Cr-1%Mo electrode. A5.5 E 8018- 2.5 13.5 4.5 65-105

Service temperature of maximum 650 C B8 3.25 15 5 110-140

o

4 15 5 150-19

Z-91 Low hydrogen electrode suitable for welding 9%Cr- A5.5 E 9015- 2.5 15 4.5 75-100

1%Mo steels, also known as GRADE 91 designed to B9 3.25 18 6 110-140

provide excellent endurance in creep, fatigue, oxidation

and corrosion resistance on high temperatures. 4 18 6 140-190