Page 7 - Product Catalog By Zika Welding

P. 7

7

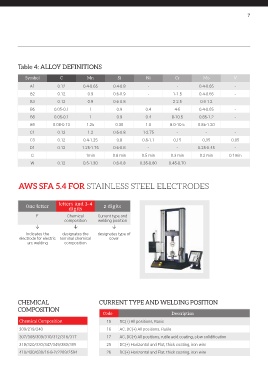

Table 4: ALLOY DEFINITIONS

Symbol C Mn Si Ni Cr Mo V

A1 0.12 0.4-0.65 0.4-0.8 - - 0.4-0.65 -

B2 0.12 0.9 0.6-0.9 - 1-1.5 0.4-0.65 -

B3 0.12 0.9 0.6-0.8 - 2-2.5 0.9-1.2 -

B6 0.05-0.1 1 0.9 0.4 4-6 0.4-0.65 -

B8 0.05-0.1 1 0.9 0.4 8-10.5 0.85-1.2 -

B9 0.08-0.13 1.25 0.30 1.0 8.0-10.5 0.85-1.20

C1 0.12 1.2 0.6-0.8 1-2.75 - - -

C3 0.12 0.4-1.25 0.8 0.8-1.1 0.15 0.35 0.05

D1 0.12 1.25-1.75 0.6-0.8 - - 0.25-0.45 -

G - 1min 0.8 min 0.5 min 0.3 min 0.2 min 0.1min

W 0.12 0.5-1.30 0.6-0.8 0.35-0.80 0.45-0.70

AWS SFA 5.4 FOR STAINLESS STEEL ELECTRODES

letters and 3-4

One letter 2 digits

digits

E Chemical Current type and

composition welding position

Indicates the designates the designates type of

electrode for electric nominal chemical cover

arc welding composition

CHEMICAL CURRENT TYPE AND WELDING POSITION

COMPOSITION

Code Description

Chemical Composition 15 DC(+) All positions, Basic

209/219/240 16 AC, DC(+) All positions, Rutile

307/308/309/310/312/316/317 17 AC, DC(+) All positions, rutile acid coating, slow solidification

318/320/330/347/349/383/385 25 DC(+) Horizontal and Flat, thick coating, iron wire

410/430/630/16-8-2/2209/2594 26 DC(+) Horizontal and Flat, thick coating, iron wire