Page 26 - Product Catalog By Zika Welding

P. 26

26

GMAW & FCAW WELDING

MIG uses a continuous coil of wire that is fed to the weld pool. The welding current is passed

onto the wire and causes an arc to establish between the two pieces. this causes the material

being welded and the wire to melt forming a molten puddle that when cooled forms the weld.

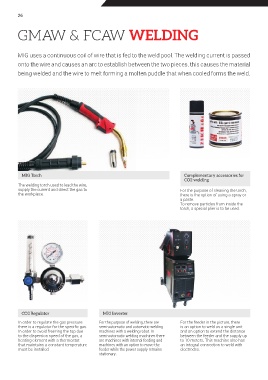

MIG Torch Complementary accessories for

CO2 welding

The welding torch used to lead the wire,

supply the current and direct the gas to For the purpose of cleaning the torch,

the workpiece. there is the option of using a spray or

a paste.

To remove particles from inside the

torch, a special plier is to be used.

CO2 Regulator MIG Inverter

In order to regulate the gas pressure For the purpose of welding, there are For the feeder in the picture, there

there is a regulator for the specific gas. semi-automatic and automatic welding is an option to weld as a single unit

In order to avoid freezing the tap due machines with a welding robot. In and an option to extend the distance

to the dispersion speed of the gas, a semi-automatic welding machines there between the feeder and the supply up

heating element with a thermostat are machines with internal feeding and to 10 meters. This machine also has

that maintains a constant temperature machines with an option to move the an integral connection to weld with

must be installed feeder while the power supply remains electrodes.

stationary.